Electrostatic Catalysis-Driven Asymmetric SEI for Dendrite-Free Lithium Metal Anodes

Chenhuan Zhou1, Yue Liu2, Pan Mei1, Yuan Zhang1, Bing Ai1, Luxi Hong1, Tao Cheng2(程涛)*, Wei Zhang1(张伟)*

1State Key Laboratory of Bioinspired Interfacial Materials Science, Innovation Center for Chemical Science, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, 215123 P. R. China

2Institute of Functional Nano & Soft Materials (FUNSOM), Jiangsu Key Laboratory for Carbon-Based Functional Materials & Devices, Joint International Research Laboratory of Carbon-Based Functional Materials and Devices, Jiangsu Key Laboratory of Advanced Negative Carbon Technologies, Soochow University, Suzhou, 215123 P. R. China

Adv. Funct. Mater. 2025, 35, 2508326

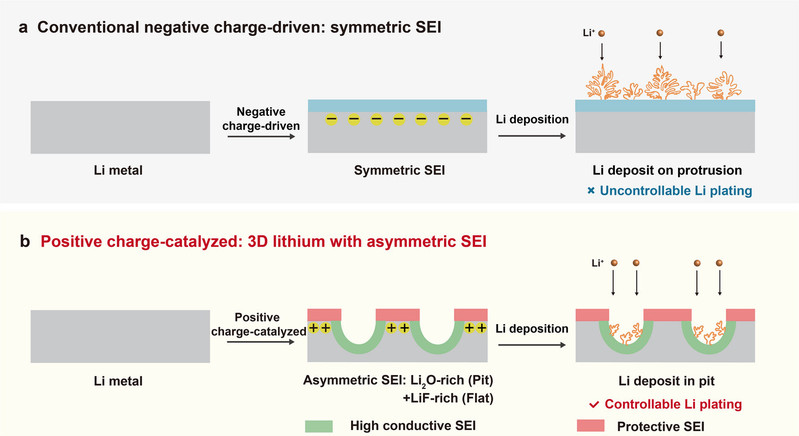

Abstract: The practical application of lithium metal anodes is hindered by uncontrolled dendrite growth, which compromises battery safety and cyclability. Conventional strategies focus on modifying electrolyte compositions or interfacial coatings but fail to fundamentally regulate lithium deposition at the nanoscale. Here, Electrostatic catalysis-driven asymmetric solid-electrolyte interphase (SEI) formation, achieved via a pulsed positive voltage pretreatment, is introduced. This process induces site-selective decomposition of electrolyte components, generating LiF-rich SEI on flat surfaces and Li2O-rich SEI in surface pits, thereby directing lithium plating into pits and suppressing dendrite formation. Experimental and computational studies reveal that electrostatic enrichment of PF6− anions at positively charged interfaces accelerates their decomposition, while pit regions, depleted of anions, promote solvent-derived Li2O formation. Lithium metal anodes with this asymmetric SEI exhibit stable cycling for over 350 h at 1 mA cm−2, outperforming conventional SEI. Full cells paired with LiCoO2 (LCO) cathodes achieve 96.1% capacity retention after 400 cycles at 1 C, compared to 56.8% for conventional SEI. These findings introduce electrostatic catalysis as a powerful interfacial engineering strategy, enabling high-performance lithium metal batteries through precise SEI control.

Article information: https://doi.org/10.1002/adfm.202508326