Flexible fibre-shaped fuel cells with gel-mediated internal pressure encapsulation

Yongjiang Yuan1, Ziyang Liu1, Xiuyang Zou2, Pengda Fang1, Jiale Zhang1, Qiuhuan Zhang1, Hao Zhang1, Qikun Yu1, Tao Zhou1, Weizheng Li1, Sijie Zheng1, Mingchen Yang1, Zhe Sun1(孙哲)*, Meifang Zhu3(朱美芳)*, Feng Yan1,3(严锋)*

1Jiangsu Engineering Laboratory of Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Negative Carbon Technologies, Suzhou Key Laboratory of Soft Material and New Energy, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou, China

2School of Chemistry and Chemical Engineering, Jiangsu Key Laboratory for Chemistry of Low-Dimensional Materials, Huaiyin Normal University, Huaian, China

3State Key Laboratory of Advanced Fiber Materials, College of Materials Science and Engineering, Donghua University, Shanghai, China

Nat. Mater.,2025, 24, 1608–1615

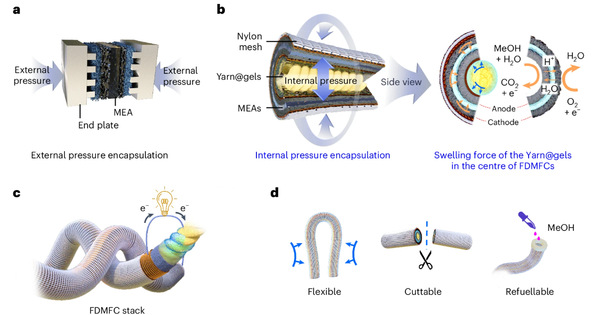

Abstract: The development of flexible fuel cells has been hindered by the rigid components and stringent requirements for pressure encapsulation and fuel sealing. Here we report an adaptive internal pressure encapsulation strategy that leverages the dynamic swelling behaviour of woven cotton fibres enclosed in a gel matrix in methanol. This strategy achieves simultaneous interfacial self-reinforcement and pressure modulation, enabling the fabrication of fibre-shaped direct methanol fuel cells. These flexible fuel cells operate across a broad temperature range, from –22 °C to 70 °C, showcasing cuttability, water resistance and fast refuelling capabilities, with full refuelling being achieved within 1 min. Furthermore, the fuel cells maintain consistent discharge performance, even after enduring 2,000 continuous flexing cycles. With an energy density of 161.36 Wh kg−1, these fibre-shaped direct methanol fuel cells surpass the energy densities of typical fibre-based power systems. This technology mitigates many of the technical challenges related to the lightweight and flexible application of fuel cells or fuel cell stacks for powering high-energy flexible devices.

Article information: https://doi.org/10.1038/s41563-025-02319-2