Exclusive Encapsulation Adhesive in a Neutral-Plane Model for Ultrahigh Mechanical Stability of Flexible Perovskite Solar Cells

Tianjiao Zhang1, Xiaofeng Pan2, Jiajia Li2, Xiaohua Tang1, Guiying Xu1(许桂英)*, Xia Lin2, Chuanshuai Han1, Wen Liu1, Tingting Xu1, Shihao Huang1, Hongyu Mou1, Yue Yin1, Jialei Zheng1, Chen Ju1, Jian Zhu2(朱健)*, Yaowen Li1,3(李耀文)*

1Laboratory of Advanced Optoelectronic Materials, Suzhou Key Laboratory of Novel Semiconductor-optoelectronics Materials and Devices College of Chemistry Chemical Engineering and Materials Science, Soochow University Suzhou 215123, P. R. China

2State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials Jiangsu Key Laboratory of Advanced Functional Polymer Design and Application Department of Polymer Science and Engineering, College of Chemistry, Chemical Engineering and Materials Science, Soochow University Suzhou 215123, P. R. China

3State Key Laboratory of Bioinspired Interfacial Materials Science Suzhou Institute for Advanced Research, University of Science and Technology of China, Suzhou 230026, P. R. China

Adv. Mater. 2025, 37, 2501776

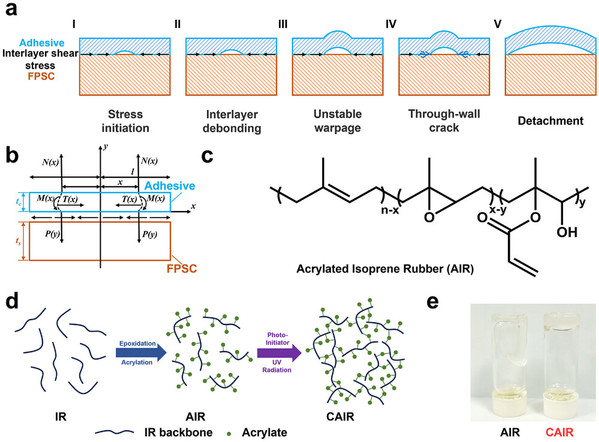

Abstract: The functional layers of flexible perovskite solar cells (FPSCs) are subjected to significant stress during bending, causing structural failure and declining power conversion efficiency. To alleviate stress, a neutral plane (NP) is introduced by positioning the functional layers at the center of the device, with top metal electrode encapsulated by a protective layer. However, adhesive detachment remains a critical issue during multiple bending cycles, and the underlying mechanism remains unclear. In this study, a systematic analysis of the detachment behavior in NP-FPSC reveals that commercial adhesives with high Young's modulus and low adhesion strength struggle to withstand interlayer shear stress during bending, which triggers detachment between adhesives and electrodes. To address this issue, a crosslinkable polymer acrylated isoprene rubber (AIR) is designed with long linear polyisoprene main chain and acrylate side chains, providing high flexibility and reduced chain segment movement. AIR can be crosslinked under UV irradiation to form a stable network with ultralow Young's modulus and high adhesion strength, ensuring a strong bond between the protective layer and FPSCs, constructing stable NP-FPSCs. The resultant NP-FPSCs demonstrate excellent mechanical stability, retaining 92.8% of their initial efficiency after 50 000 bending cycles at a radius of 4 mm, meeting the IEC 62715-6-3 standards.

Article information: https://doi.org/10.1002/adma.202501776