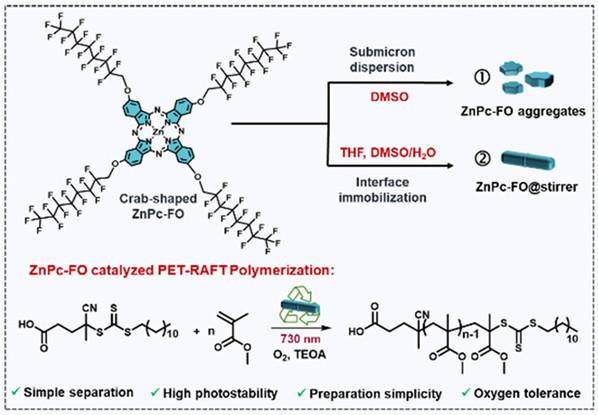

Fluorinated Phthalocyanine as a Catalyst for NIR-Photocontrolled PET-RAFT Polymerization: From Submicron Dispersion to Surface Immobilization

Shunhu Zhang1, Deqian Xu2, Lishuang Guan1, Nailin Yang3(杨乃霖)*, Weiwei He2(何伟伟)*, Lifen Zhang1(张丽芬)*, Zhenping Cheng1(程振平)*

1State and Local Joint Engineering Laboratory for Novel Functional Polymeric Materials, Jiangsu Key Laboratory of Advanced Functional Polymer Materials, Suzhou key Laboratory of Macromolecular Design and Precision Synthesis, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou 215123, China

2State Key Laboratory of Radiation Medicine and Protection, School of Radiological and Interdisciplinary Sciences (RADX), Soochow University, Collaborative Innovation Center of Radiological Medicine of Jiangsu Higher Education Institutions, Suzhou 215123, China

3Institute of Functional Nano & Soft Materials (FUNSOM), Jiangsu Key Laboratory for Carbon-Based Functional Materials and Devices, Soochow University, Suzhou 215123, China

Macromolecules2025, 58, 23, 12765–12775

Abstract: To address the issues of low efficiency and difficult recovery of photocatalysts in near-infrared (NIR) photoinduced electron/energy transfer reversible addition–fragmentation chain transfer (PET-RAFT) polymerization, this work develops a series of fluorinated phthalocyanines to optimize the photostability and photocatalytic performance to serve as efficient and recyclable catalysts. Among them, 1H,1H-pentadecafluorooctyl-modified phthalocyanine exhibits a significantly enhanced reactive oxygen species generation efficiency and photostability, which can form submicrometer aggregates(~710 nm) in the polar solvent dimethyl sulfoxide. The zinc 2,9,16,23-tetra[(1H,1H-pentadecafluorooctyl)oxy]-phthalocyanine (ZnPc-FO)-mediated PET-RAFT polymerization can achieve high monomer conversion in the presence of oxygen within 4 h (up to 98%) and controlled polymerization (Đ ≤ 1.25). A key breakthrough lies in facilely anchoring ZnPc-FO onto the surface of a poly(tetrafluoroethylene) (PTFE) stirrer by taking advantage of unique fluorine–fluorine (F–F) interactions, which greatly simplifies the recycling operation after polymerization, and up to 90% monomer conversion can be maintained even after 12 noncontinuous cycles. This kind of fluorinated phthalocyanine provides an efficient and recyclable catalyst for NIR light-mediated PET-RAFT polymerization.

Article information: https://doi.org/10.1021/acs.macromol.5c02545